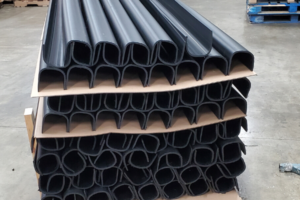

Alpha Plastics Solutions, Inc. manufactures quality custom plastic extrusions, extruded profiles and extruded plastic tubing solutions for customers worldwide.

Producing quality extrusions in tube and custom profiles, using a variety of extrusion processes, as well as additional in-line processes. Working with a wide array of plastics and thermoplastics, we manufacture profiles up to 4″ x 10″ x 6″ while maintaining tolerances of ±.060″.

For large or long term production we offer a stocking option, as well as many additional finishing capabilities. For more information on all of our precision extruded plastic capabilities, see the table below or contact us directly.