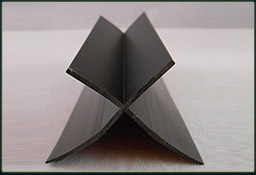

A customer in the building ventilation industry needed a precision extruded PVC gasket manufactured for one of their ventilation systems.

The product, a core X-flange gasket, required close tolerance extrusion as well as several secondary manufacturing processes. This complex part was composed of ridged and flexible PVC. The rigid PVC was black in color with a 94-5V rating, and required a minimum thickness of 0.03″. The flexible PVC section which was a GA-1264FR thermoplastic was also 94-5V rated and flame retardant.

The gaskets were manufactured utilizing our extrusion capabilities as well as routing and punching to meet the various critical tolerances. The finished parts measured 21.688″ in length (+ 0.000″/- 0.030″), and 1.925″ in width and height (±0.050″).

Other tolerances included a maximum curvedness of .63″, and tight tolerances of + 0°/- 5° angular, and ± 0.015″. The customer required 2500 finished pieces which we produced at 165 parts per hour. For more information on this project, see the table below or contact us directly.