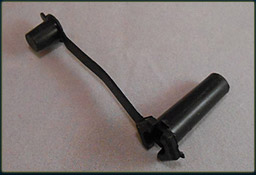

The component shown here is a product of our precision injection molding capabilities, and was designed for use as a pressure port in a building ventilation system.

Formed from a TBD plastic with a UL95-5V rating, it measured .500″ in length, .625″ in width, and 1.200″ in height. The finished part met tolerances of ± 0.003″, and featured a 63 microinch finish. Quality was maintained through in-process dimensional inspection, and part integrity was verified with air leak testing.

1000 of these components were manufactured at a rate of 180 pieces per hour, for our customer in the Midwest. For more information on this product, see the table below or contact us directly.